SHIELED METAL ARC WELDING (SMAW)

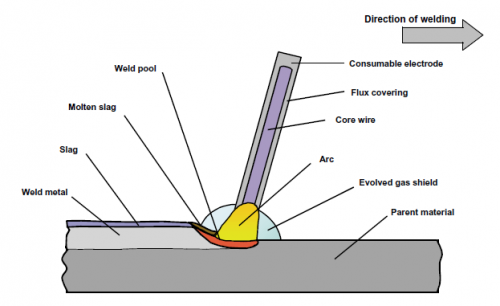

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW) This process remains the most versatile of all welding processes but its use in the modern workshop is limited. Alternating current transformers, DC rectifiers or inverters supply electrical power along a cable to an electrode holder or tongs. A flux coated wire electrode (or "stick") is inserted in the holder and a welding arc is established at the tip of the electrode when it is struck against the work piece. The electrode melts at the tip into a molten pool, which fuses with the parent material forming the weld. The flux also melts, forming a protective slag and generating a gas shield to prevent contamination of the weld pool as it solidifies. Flux additions and the electrode core are used to influence the chemistry and the mechanical properties of the weld.

Hydrogen controlled basic coated electrodes are generally used. It is essential to store and handle these electrodes in accordance with the consumable manufacturer’s recommendations in order to preserve their low hydrogen characteristics. This is achieved either by using drying ovens and heated quivers to store and handle the product, or by purchasing electrodes in sealed packages specifically designed to maintain low hydrogen levels. The disadvantages of the process are the relatively low deposition rate and the high levels of waste associated with the unusable end stubs of electrodes. Nevertheless, it remains the main process for site welding and for difficult access areas where bulky equipment is unsuitable.